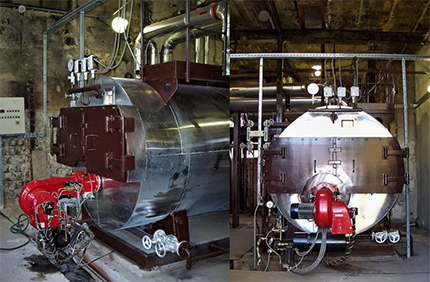

TIPO KOTLOGRADNJA is company for the design, manufacture, assembly, repair and reconstruction of boilers and power plants. It was founded in 1979. In the initial period is performed repairs of boiler plants to 1990, beganits own production of industrial boilers. On the day of the foundation, set up the program orientation and business strategy that reflects the company motto: YOUR ENERGY SECURITY and that means always be first in the group and achieve global results.

- In addition, liboaljadeeda LIBOINTARA team can consultant and support the customer and give him the advice to development Oil and Gas field as following below:

- TodayTIPO KOTLOGRADNJA is one of the leading companies in Serbia in the field of boilers.

Win a large number of new product that are an integral part of the production program of its appearance, quality and characteristic are recognized in the market.

The production program includes the production of boilers for all types of fuel.

We design and produce:

steam, boiled water, hot water, thermal oil and electric boilers; pressure vessels; heat excangers; other supporting equipment for boilers and parts of the production process.

-

All products from the productions of the work of professionals employed in the enterprise

TIPO KOTLOGRADNJA.

The quality of products is based on a rich reference list of performed works, proven quality, respect for deadlines and other contractual obligations.

The results so far have been achieved policy of company to continuously work on improving engineering and other technical personnel, modernization of equipmen, introduction of new technologies and application of new materials.

-

The shortest delivery times, highest quality according to SRPS and ISO standards, with modern and certified equipment, allows providing garranty on all equipment that we supply and jobs we peform.

All products are designed to meet individual customer requirements, are easy to operate and maintain a high degree of automated operation.

Depending on the available fuel, or a mixture of different types of fuel will choose the appropriate equipment to enable smooth and long lasting operation of the plant.

-

PRODUCTS PROGRAM

- PREPARATION OF FUEL

- Wood chipper

- Storage of straw

- Presses for solid waste

- Metal separator

- Non-metal separators

-

STORAGE AND TRANSPORT OF FUEL

- Warwhouse with automatic crane

- Warehouse with a moving floor

- Treadmills

- Chain choveyors

- Screw choveyors

-

COMBUSTION EQUIPMENT

- ■Hydraulic fuel dispensers

■ Srew dosers fuel

■ Grate combustion

■ Conveyors ash

■ Fans of fresh air

■ Fans flue gases

■ Regulation klappe

- BOILERS

■Hot water boilers

■ Boiled water

■ Steam boilers

■ Thermal oil boilers

FILTERING THE FLUE GASES

- Multicyclone

- Baghouse filters

- Scrubbers

- Lime dosing

- Continuous measurement of emissions

-

OTHER

- ■

Management and control systems

■ Water treatment

■ Expansion tank

■ Tank

■ Containers

■ Heat accumulators

■ Heat exchanger

■ Chimneys and smoke pipes

■ Fresh air channels

■ Steel construction

Important place in our production program in renewable energy sources:

PARK FOREST BIOMASS

-Burning leaves and small branches

-Burning large pieces of wood

-Burning wood chips

-Combustion of pellets and briquettes

-Combustion residues fruit

AGRICULTURAL BIOMASS

The remains of the plant parts:

-Wheat straw

-Soybean straw

-Corn

-Sunflower husk

And the burning of pellets made from the parts of these plants

IN OUR RANGE OF PRODUCTS USING THE EXPERTISE AND KNOWLEDGE OF OUR EMPLOYEES WE HAVE PRODUCED:

Plant for baled straw power -- 3 MW PKB Beograd

Plant on wood chips power -- 7 MW FKA Bitolj

Plant in agro pellet power -- 3 MW Veterinarski Zavod Subotica

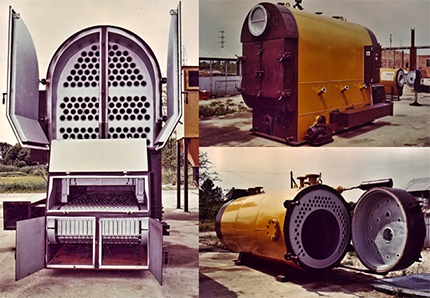

STEAM BOILERS

Steam boilers products on all type of fuel (solid, liquid, gases) steam production from 50 kg/h to 63 t/h operating pressure from 0.5 bar to 74 Three – pass block boiler type PKT S with floating chamber intended for the production of steam from 500 kg/h to 20 t/h working pressure from 0.5 bar to 13 bar (25 bar). Fuel: liquid, gases. Three – pass block boiler type PKT E with a screen chamber intended for the production of steam from 8 t/h to 35 t/h, working pressure 6 – 13 bar (the requirements to 25 bar) saturated steam or superheat steam to 350oC. Fuel liquid, gases.

Three – pass block boiler type TPR with fixed flat grille are intended for the production steam from 0,65 to 3 t/h, working

pressure from 6 to 13 bar.

Fuel: coal

Three – pass block boiler type MAG MP with a sreen chamber and movable grate mechanical production from 1,0 to 3,0 t/h working pressure0,5 bar.

Fuel: coal

Tree – pass block boiler type MAG RP with fixed flat grille are intended for the production steam from 100 to 1.000 kg/h, working pressure 0,5 bar.

Fule: coal

TPD type tube boiler are made with two drums, of which the lower and the upper water vapor. The firebox is made or impermeable membrane walls of the flue gases. Production of steam - type TPD ranges from 18 to 63 t/h operating pressure 10 to 74 bar.

Fuel: liquid, gases

STEAM BOILERS

Tube boiler type TPU produced with two drums and tubular beam between them. Firebox is in membrane performance, as well as outside of the tube bundle. Production of steam boilers type TPU rangers from 15 to 30 t/h, operating pressure 16 to 35 bar.

Fuel: coal

Tube boiler type TPP producied with one drum and the membrane firebox. Production of steam boilers type TPP of 3,2 to 8 t/h, operating pressure up to 13 bar.

Fuel: coal, sawdaust, wood waste

Electrical boiler type VAT P production of 50 to 500 kg/h pressure 4 to 10 bar.

Fuel: el.energy 3x380V

HOT WATER BOILERS

Three – pass block boiler type

VKT S with floating chamber intended for the production of hot water power 0,5 to 10,5 MW, operating pressure up to 13 bar.

Fuel: liquid, gases.

Three – pass block boiler type

VKT E whit sreen chramber intended for the production of hot water power 12 to20 MW, operating pressure up to 13 bar.

Fuel: liquid, gases.

Three – pass block boiler type TVM intended for the production of hot water power 1 to 15 MW, operating pressure up to 13 bar.

Fuel: liquid, gases.

Tube boiler type TMV are vertical membrane boilers designed for the production of hot water power 20 to 60 MW, operating pressure up to25 bar.

Fuel: liquid, gases.

Tube boilers type TME are horizontal membrane boilers designed for the production of hot water power 2 to 20 MW, operating pressure up to 25 bar.

Fuel: liquid, gases.

Tube boilers type TMH are horizontal membrane boilers designed for the production of hot water power 20 to 60 MW, operating pressure up to 25 bar.

Fuel: liquid, gase.

Eletrical boilers type VAT V intended for the production of hot water power 0,2 to 1 MW, operating pressure up to 6 bar. Fuel: el.energy 3x380V.

Three – pass block boilers type TKT with floating chamber intended for the production of hot water power 0,35 to 3,0 MW, operating pressure up to 6 bar.

Fuel: liquid, gases.

Three – pass block boilers type TVN with floating chamber intended for thr production of hot water power 3,5 to 15 MW, operating pressure up to 6 bar. Fuel: liquid, gases.

Three – pass block boilers type MAG R with fixed flat grille are intended for the production of hot water power from 0,2 to 1 MW, operating pressure up to 3 bar.

Fuel: coal

Three – pass block boilers type MAG M with movable mechanical grille are intede for the production of hot water power from 0,9 to 1,75 MW, operating pressure up to 3 bar.

Fuel: coal

Three – pass block boilers type TVP with a piece of mechanical grille are intended for the production of hot water power from 0,3 to 2,5 MW, operating pressure up to 6 bar.

Fuel: biomass, sawdaust, wood waste, soybean straw

Electrical boilers type VAT T intended for the production of hot water power 0,2 to 1 MW, operating pressure uo to 6 bar.

Fuel: el.energy 3x380V.

THERMAL OIL BOILERS

Three – pass boilers type FAST-U intended for the production of thermal oil for technological consumers. Is produced in a series of 0,27 to 900 kW, operating pressure up to 6 bar and tmax=250oC.

Fuel: liquid, gases

Electrical boiler type VAT-U intended for the warming thermal oil for technological consumers. Is produced in a series of 0,3 to 1 MW, operating pressure up to 6 bar and tmax=250oC.

Fuel: el.energy 3x380V.

UTILIZATOR

For all boilers fueled by natural gasis possible to install heat utilizerwich would cool the flue gas to a drew point wich achieves high efficiency and reducing heat losses in the flue gases below 5%

They are made of spiral finned tubes with steel ribs are continuously welded pipe. At the request of the customer can be on the outside of hot zinc.

They are characterized by a large surface to the space they occupy.

Products like heating surface with in the boiler or as separate structures.Watchers do to boilers from 0,5 to 116 MW.

VESSEL

- As part of the production program of the company TIPO KOTLOGRADNJA manufactures and courts with in the boiler or special request as follows:

- Heat accumulators

- Expansion tank

- Ion excange filters

- Salt container

- Feed water tank

- Thermal gas separators

- Condensate reservoirs

- Air tanks

- Sand filters

- Hydrophore tanks

- Splitter steam/ water

- Hot water heaters (electrical, steam, hot water,combined)

- Steam separators

- Expanders condensate

- Separators liquid ammonia / receivers

- Storage tanks of heavy / light heating oil

- Reheater fuel oil

- Heating excange